Site map :

Last upgrade to the site:

august 10th, 2002.

There has been

access to my Lego pages since creation.

This is an unofficial LEGO® web site.

LEGO® is a trademark of the LEGO® Group of companies

which does not sponsor, authorize or endorse this site.

You can visit the official LEGO website at: http://www.lego.com

Copyright 1996, 2000, Denis Cousineau

| |

Tutorial 1:

What to make to obtain a Computer-controlled robot

|

A computer controlled-robot involves the realization of three

distinct units:

- The robot itself: see my Robot section;

- The controller physical driver that connect

the robot to the computer

- The computer interface which decides the

actions of the robot.

-

I would like to thanks M. Paquette from College de L'Assomption for

some hints on the use of transistors.

The controller is responsible to establish the link between computer and

the robot. The reason for that is that the computer outputs only a few mA, not

enough to start most motors. Therefore, a supply of power is usually appended

to the controller (a 9volts, 1A in the case of Lego motors which are simple DC

motors).

-

Choosing the motors

Before making a controller, you must choose what type of motors you want to

use; your design will greatly depend on it. Stepper motors are motors

whose rotation can be controlled with a high precision. However, they require

a pretty complex controller. Servos are pretty weird motors, since they

can rotate no more than 360 degrees. They are useful for short motion, but are

clearly counter-indicated for propelling a car! I did not found circuit

information for controlling servos. DC motors are the most simple to

control. Presence of voltage on one input makes them turn. They are however

very imprecise.

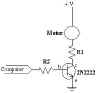

The simplest way to control a dc motor is thru the use of a transistor.

Transistors act like switches. In the first figure, R1 is a 1 kilo-ohms

resistance, and R2 is any small resistance (10-300 ohms). Q1 is a very common

type of transistor: a 2N2222. See part

list for a drawing of these, and this

for a picture. A transistor costs no more than 50 cents.

In order to control bi-directional a motor (ON/OFF, and clockwise or

counterclockwise), a H-type circuit is needed. In the second picture, if both

upper left and lower right transistors are ON, the current will flow through

the motor from left to right, yielding a CW rotation.

Trouble is that there is a lost of power. I have not been able to sink more

than 500 mA through the motor in the H circuit. It is enough for small motors,

but not for the Lego-type motors who need a full 1 ampere of

current.

One alternative is to replace transistors with power-mofset. I haven't try,

but you might look at MOSFET

H-Bridge Schematic & Theory of Operation for more. Another alternative

that I explored in tutorial 2 is to use a mechanical switch to control the

direction of motion. Relays are electro-magnetic switch that can be controlled

easily with a transistor. Since the current is independent of the

transistor-magnet circuit, there is no lost of power.

For more on stepper motors, see Controllers

for servos motors with commercial drivers.

-

Choosing communication port

Choosing a mean of communication. Our computer needs to communicate to the

controller. The two likely methods are to use the ports available. There is

two kind of port. The parallel port (or printer port) is easy to program, but

has a limited capacity at any given time. In the best case, it can only output

8 bits of information, and can input from sensor 8 bits.

-

Choosing the kind of sensors you need.

There is a large variety in sensors, ranging from electronic thermometer to

pressure sensors. The simplest kind is the on/off sensors. When pressure is

applied, the switch turns on. One bit of information is enough per

sensor.

Programming a computer-controlled robot can involves many embedded

programs, or layers.

-

Basic moves / reading sensors

The lowest level is basically a software that can send command to the

controller, or receive data from the sensors. Otherwise said, it is a

program that operates your parallel port (or serial port, whichever is

connected to your controller), using meaningful commands such as TURN(30),

START(2), IS_ON?(1), etc. It is best seen as a repository of what can be

done by your robot. In WINDOWS, a good programming habit is to place these

commands as functions in a library. Commands in libraries are retrieved

whenever needed by any other program (higher layers). This type of library

is called DLL (Dynamically linked library); the resulting file have to be

located in the \WINDOWS or \WINDOWS\SYSTEM directory.

- Most compilers can produces DLL. For example, in Pascal, you start

with the word library LEGO; then type in the functions needed.

If you want to be able to use functions in library, you have to declare them

external. For example, in Visual Basic, you write in the (general

declaration) section: Function ABOUT: integer EXTERNAL "LEGO"

where Lego is the name of the DLL file.

The instruction you are likely to use in your library is PORT. That

instruction can send or receive data from a computer parallel port. For

example (in QBasic):

PORT &H3F8, 9

sends 00001001 to the first eight bits of the parallel port.

With a serial port, use file access procedure OPEN:

OPEN "COM1:9600,N,8,1" FOR RANDOM AS #1

PRINT #1,9

sends 00001001 to the COM1 port, at a speed of 9600.

In my LEGO.DLL (see that),

I programmed the procedure START(x) that light the motor number x using

these procedures (in Pascal):

function START (x: motor_no): integer; export;

{light the motor x; use STOP to stop it}

var mask, i: byte;

begin

if (x<1)or(x7) then START := -4

else

if base <= 0 then START := -3

else begin

mask:=1;

for i:=1 to x-1 do mask:= mask*2;

motor_state := motor_state or mask;

output_motor_state;

START:=0;

end;

end;

procedure output_motor_state;

{note that the last bit of port[base] is for the reverse of direction pin 9}

var mask: byte;

begin

port[base]:= motor_state;

end;

base is the address of the port, determined by the INIT procedure (not

shown here). If an error occurs, that is, if the function does not return

zero, use ERROR(nbre returned). ERROR is available in the DLL, and contains

a list of all the possible error with an explanation. The variable

MOTOR_STATE keeps tracks (in binary) of all motor states. For example,

00000001 means the last motor is ON while all other are OFF.

-

Sending commands/receiving data

The first layer is only a list of what can possibly be done with your robot.

Now we need to send specific commands to your robot.

Commands can be very simple, such as "Start motor 3 now", or

more complex, such as "Start motor 3, wait 5 seconds, start motor

2, and when sensor 2 gets on, stop all moves."

The VBASIC interface that I proposed in another page is an example which can

send only simple commands. A better interface would accept commands such as

"Turn motor 3 for x seconds" or "Turn motor 3 until sensor 2

gets on".

-

Constraint control

Not all moves are safe for the health of your robots. For example, turning

the arm to the left for an indefinite time is risky if your arm cannot do

more than 360 degree turns (and most arms can not do that much).

In order to avoid wreckage, your robot should know things about its

limitations. These are called constraints. Example of constraints are:

If the base is turning for more than 5 seconds, then you ought to stop

turning the base.

If the sensor in the hand feel excessive pressure, you ought to stop

grasping. Constraints are easily expressed in the form "If … you ought to

…". It is like a watching device that monitors the commands sent

by the layer B so that no crash occurs. This layer should never be seen

but always be on.

-

Artificial intelligence

Here I refer to giving some brain to your computer-robot. I can think of

two kind, both related to machine learning. The first is learning new higher

level commands, such as PICK, which is a string of various low-level

commands. This learning could be performed by noting that some strings are

common, and thus the machine should be asking the human a new name for it.

The second type of learning is learning the constraints the robot must

obey. This could be achieved by sending signals that could be termed

"Pain" and let the robot figure out what sensors or movement

started it.

|