The 1-to-2 multiplexor can multiply by two the RCX outputs. However, these

outputs are slow, so we would like to keep one output straight, and have the

other one controlling stuff where speed is not crucial.

The following devices can control up to 7 motors. They can be extended

to 9 without any changes. However, they are controlled using two of the RCX

output. Therefore, there is only one remaining output on the RCX.

The general idea is to have a kind of selector that can divert one motor

onto one of seven possible gear, the actual output. The second motor (motor B)

can then be turned on, forward or backward.

Design I

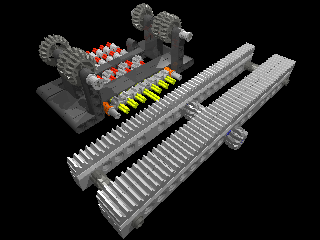

In order to do so, the following mechanism uses a horizontal slider that

can move left or right:

The back gear touches Motor B, whatever position it is on, using this back:

Motor B connects on top of the Figure and makes all the 8-teeth gears turn.

The front of the slider connects to one of the 7 outputs, and only one at a

time, depending on its position on the front part:

Connecting these three parts, we obtain:

The slider can move left or right owing to the rack on its side, which

connects to the motor A. On the right of the slider, we can see

"balls". The are use to make the slider stops at a correct position

and not in-between (otherwise, Motor B is jammed).

The above picture shows the stepper added to block the "balls" at

legal positions (see pages on stepper motors). Are missing the motor B on the

back and motor A on the top.

Design II

The following design is much more compact but requires many of the new Lego

beams (with no studs on it).

The POV rendering shows the same with the slider placed in front of it. The

LDRAW plans are provided in this file: multi_v2.dat

Design III

This is the best design so far. The trouble with Design I and II is that

the gears don't always mesh perfectly. Thus, on some occasion, two tooth

arrive head-to-head (so to speak). Then, a lot of torque is required to move

the slider in its position. Since these events are unpredictable, it means

that on some occasion, the motor that moves the slider left or right will not

be strong enough, and the slider will no longer be aligned. Using a sensor of

some kind would alleviate this problem. Yet, I prefer to have a design which

does not have this problem so that I can use a sensor elsewhere.

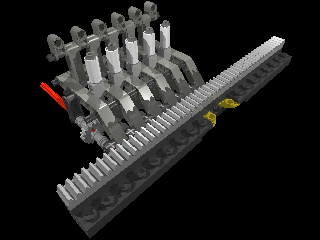

The following design does not have this problem. It is based on the gearbox

pieces:

The gray gear in front is turned. However, as long as the lever arm is not

pushed back, this has no influence on the output (here, the output would be

the black axle in the front of the picture). This arrangement can be repeated

many times (5 times below).

Using rubber bands, the levers tend to go back. I used a slider which

allows only one lever to be in the back position at a time, thus engaging a

single output at a time.

Here, the slider is shows in front of the multiplexor, but should be

inserted behind the levers, mounted with white tubes. Finally, the red axle is

the input, turning all the gray gears.

The full design is shown in multi_v3.dat

Mario Ferrari published a prototype similar to Design I in his book. However, it has

some drawbacks. a) the slider was too tightly hold, requiring a very strong

motor to make it turn; b) it was limited to only 5 outputs, and difficult to

expand; but more importantly, c) it required a RCX input (a touch sensor) to

detect when the slider is in a legal position. The design III does

not need a sensor to stop the slider in a good position. Timing is

sufficiently accurate.